Title: Exploring Popular Models of Dedicated Transformers

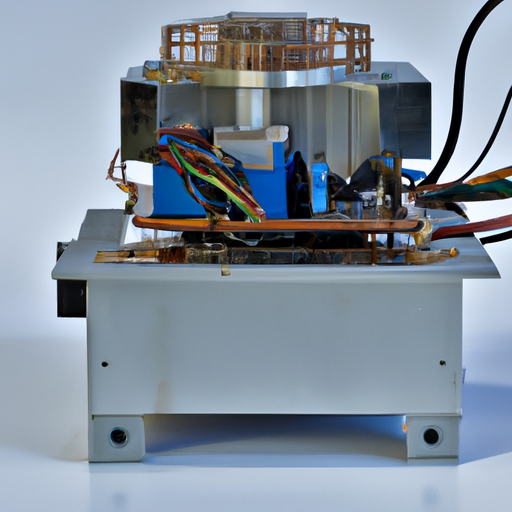

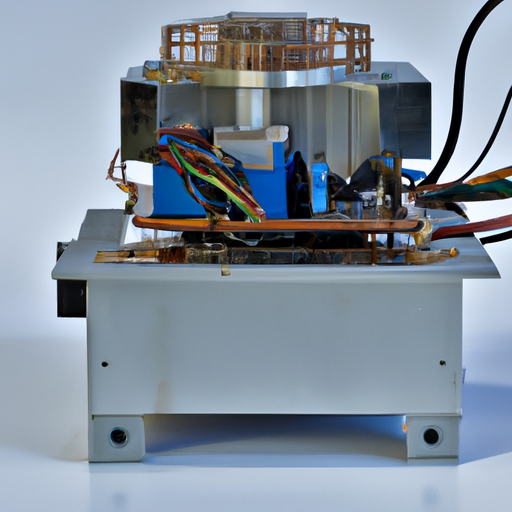

1. Dry-Type Transformers (200 words) Dry-type transformers are widely used in commercial and industrial applications due to their safety, reliability, and ease of maintenance. These transformers use air as the cooling medium, eliminating the need for oil-filled tanks. They are suitable for indoor installations, where fire safety is a concern. Dry-type transformers are available in various sizes and voltage ratings, making them versatile for different applications. They are commonly used in hospitals, schools, data centers, and other sensitive environments.

2. Oil-Filled Transformers (200 words) Oil-filled transformers are the most common type of transformers used in power distribution networks. They are filled with mineral oil, which acts as both an insulator and a coolant. These transformers are highly efficient and can handle high power loads. Oil-filled transformers are typically used in outdoor installations, such as substations and power plants. They are designed to withstand harsh weather conditions and provide reliable power transmission over long distances.

3. Step-Up and Step-Down Transformers (200 words) Step-up and step-down transformers are essential for voltage conversion in power distribution systems. Step-up transformers increase the voltage level, allowing efficient long-distance transmission, while step-down transformers decrease the voltage for safe utilization by end-users. These transformers are commonly used in electrical grids, ensuring efficient power transfer from generation plants to distribution networks and ultimately to consumers.

4. Three-Phase Transformers (200 words) Three-phase transformers are designed to handle three-phase power systems, which are commonly used in industrial and commercial applications. These transformers have three sets of primary and secondary windings, enabling efficient power distribution across three phases. Three-phase transformers are known for their high efficiency, compact design, and ability to handle heavy loads. They are widely used in manufacturing plants, large commercial buildings, and industrial facilities.

5. Autotransformers (200 words) Autotransformers are a cost-effective solution for voltage conversion, where a portion of the winding is shared between the primary and secondary sides. These transformers are smaller and lighter compared to conventional transformers, making them suitable for applications where space is limited. Autotransformers are commonly used in voltage regulation, motor starting, and variable speed drives. They offer high efficiency and are often preferred in applications where cost and size are critical factors.

Conclusion (100 words) Dedicated transformers are essential components in power distribution systems, ensuring efficient and reliable electricity supply. Understanding the different models of dedicated transformers, such as dry-type transformers, oil-filled transformers, step-up and step-down transformers, three-phase transformers, and autotransformers, is crucial for selecting the right transformer for specific applications. Each transformer model has its unique features, benefits, and applications, catering to diverse industry needs. By considering these popular transformer models, businesses can optimize their power distribution systems, enhance safety, and improve overall operational efficiency.

Title: Exploring Popular Models of Dedicated Transformers

1. Dry-Type Transformers (200 words) Dry-type transformers are widely used in commercial and industrial applications due to their safety, reliability, and ease of maintenance. These transformers use air as the cooling medium, eliminating the need for oil-filled tanks. They are suitable for indoor installations, where fire safety is a concern. Dry-type transformers are available in various sizes and voltage ratings, making them versatile for different applications. They are commonly used in hospitals, schools, data centers, and other sensitive environments.

2. Oil-Filled Transformers (200 words) Oil-filled transformers are the most common type of transformers used in power distribution networks. They are filled with mineral oil, which acts as both an insulator and a coolant. These transformers are highly efficient and can handle high power loads. Oil-filled transformers are typically used in outdoor installations, such as substations and power plants. They are designed to withstand harsh weather conditions and provide reliable power transmission over long distances.

3. Step-Up and Step-Down Transformers (200 words) Step-up and step-down transformers are essential for voltage conversion in power distribution systems. Step-up transformers increase the voltage level, allowing efficient long-distance transmission, while step-down transformers decrease the voltage for safe utilization by end-users. These transformers are commonly used in electrical grids, ensuring efficient power transfer from generation plants to distribution networks and ultimately to consumers.

4. Three-Phase Transformers (200 words) Three-phase transformers are designed to handle three-phase power systems, which are commonly used in industrial and commercial applications. These transformers have three sets of primary and secondary windings, enabling efficient power distribution across three phases. Three-phase transformers are known for their high efficiency, compact design, and ability to handle heavy loads. They are widely used in manufacturing plants, large commercial buildings, and industrial facilities.

5. Autotransformers (200 words) Autotransformers are a cost-effective solution for voltage conversion, where a portion of the winding is shared between the primary and secondary sides. These transformers are smaller and lighter compared to conventional transformers, making them suitable for applications where space is limited. Autotransformers are commonly used in voltage regulation, motor starting, and variable speed drives. They offer high efficiency and are often preferred in applications where cost and size are critical factors.

Conclusion (100 words) Dedicated transformers are essential components in power distribution systems, ensuring efficient and reliable electricity supply. Understanding the different models of dedicated transformers, such as dry-type transformers, oil-filled transformers, step-up and step-down transformers, three-phase transformers, and autotransformers, is crucial for selecting the right transformer for specific applications. Each transformer model has its unique features, benefits, and applications, catering to diverse industry needs. By considering these popular transformer models, businesses can optimize their power distribution systems, enhance safety, and improve overall operational efficiency.