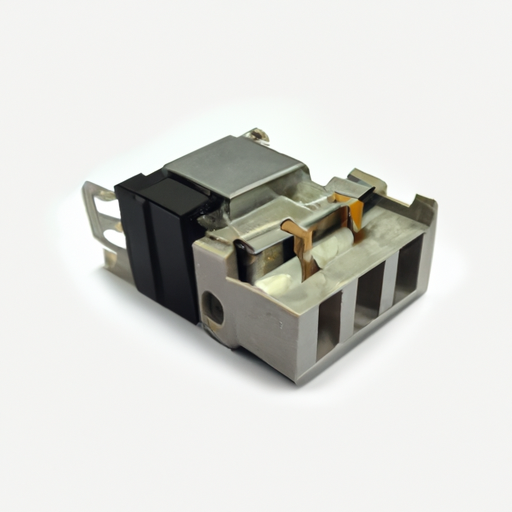

Title: Understanding Product Standards for Relay Sockets: A Comprehensive Guide

1. Importance of Product Standards (200 words) Product standards are essential for relay sockets as they ensure consistent quality, reliability, and compatibility across different manufacturers and applications. These standards are developed by international organizations, such as the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI), to establish a common set of requirements for relay socket manufacturers to follow. Compliance with these standards guarantees that relay sockets meet specific performance criteria, ensuring safe and efficient operation.

2. Key Specifications and Standards (400 words) a. Mechanical Specifications: Relay sockets must conform to specific mechanical dimensions, such as pin spacing, socket size, and mounting options. These specifications ensure proper fitment and compatibility with relays and circuit boards.

b. Electrical Specifications: Electrical standards define the maximum voltage and current ratings, contact resistance, insulation resistance, and dielectric strength of relay sockets. These specifications ensure that relay sockets can handle the required electrical loads without compromising safety or performance.

c. Environmental Specifications: Relay sockets may need to operate in harsh environments, such as high temperatures, humidity, or corrosive conditions. Standards define the environmental specifications, including temperature range, humidity resistance, and protection against dust and moisture, to ensure reliable operation in such conditions.

d. Safety Standards: Safety is of utmost importance in electrical systems. Relay sockets must comply with safety standards, such as UL (Underwriters Laboratories) or CE (Conformité Européene), to ensure protection against electrical shock, fire hazards, and other potential risks.

e. RoHS Compliance: The Restriction of Hazardous Substances (RoHS) directive restricts the use of certain hazardous substances in electrical and electronic equipment. Relay sockets must comply with RoHS standards to ensure they are free from harmful substances like lead, mercury, cadmium, and others.

3. Benefits of Complying with Product Standards (300 words) a. Interchangeability: Standardized relay sockets allow for easy interchangeability between different manufacturers, reducing the risk of compatibility issues and simplifying maintenance and replacement procedures.

b. Reliability and Performance: By adhering to product standards, relay socket manufacturers ensure that their products meet specific performance criteria, resulting in reliable and consistent operation. This reliability is crucial in critical applications where system failure can have severe consequences.

c. Safety Assurance: Compliance with safety standards guarantees that relay sockets are designed and manufactured to meet stringent safety requirements, minimizing the risk of electrical hazards and ensuring user safety.

d. Global Acceptance: International product standards provide a common language for manufacturers, suppliers, and customers worldwide. Complying with these standards ensures global acceptance and facilitates trade across different regions.

e. Regulatory Compliance: Many industries have specific regulations and standards that must be met. By using relay sockets that comply with relevant product standards, manufacturers can ensure compliance with industry-specific regulations, avoiding legal and regulatory issues.

Conclusion (100 words) Relay sockets are critical components in electrical systems, and adherence to product standards is essential to ensure their reliability, compatibility, and safety. By understanding the importance of product standards, key specifications, and the benefits they offer, engineers and technicians can make informed decisions when selecting relay sockets for their applications. Compliance with these standards not only ensures optimal performance but also contributes to the overall efficiency and longevity of electrical systems.

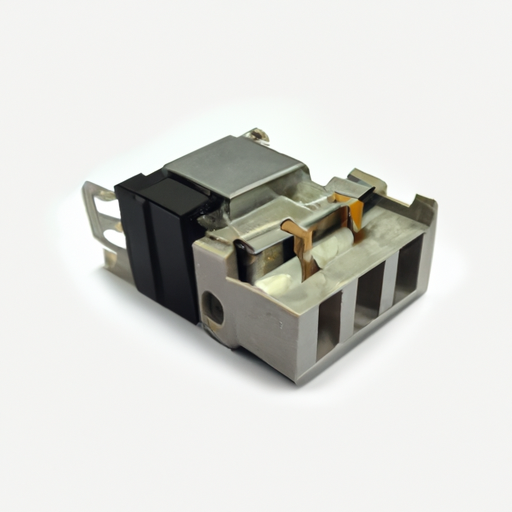

Title: Understanding Product Standards for Relay Sockets: A Comprehensive Guide

1. Importance of Product Standards (200 words) Product standards are essential for relay sockets as they ensure consistent quality, reliability, and compatibility across different manufacturers and applications. These standards are developed by international organizations, such as the International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI), to establish a common set of requirements for relay socket manufacturers to follow. Compliance with these standards guarantees that relay sockets meet specific performance criteria, ensuring safe and efficient operation.

2. Key Specifications and Standards (400 words) a. Mechanical Specifications: Relay sockets must conform to specific mechanical dimensions, such as pin spacing, socket size, and mounting options. These specifications ensure proper fitment and compatibility with relays and circuit boards.

b. Electrical Specifications: Electrical standards define the maximum voltage and current ratings, contact resistance, insulation resistance, and dielectric strength of relay sockets. These specifications ensure that relay sockets can handle the required electrical loads without compromising safety or performance.

c. Environmental Specifications: Relay sockets may need to operate in harsh environments, such as high temperatures, humidity, or corrosive conditions. Standards define the environmental specifications, including temperature range, humidity resistance, and protection against dust and moisture, to ensure reliable operation in such conditions.

d. Safety Standards: Safety is of utmost importance in electrical systems. Relay sockets must comply with safety standards, such as UL (Underwriters Laboratories) or CE (Conformité Européene), to ensure protection against electrical shock, fire hazards, and other potential risks.

e. RoHS Compliance: The Restriction of Hazardous Substances (RoHS) directive restricts the use of certain hazardous substances in electrical and electronic equipment. Relay sockets must comply with RoHS standards to ensure they are free from harmful substances like lead, mercury, cadmium, and others.

3. Benefits of Complying with Product Standards (300 words) a. Interchangeability: Standardized relay sockets allow for easy interchangeability between different manufacturers, reducing the risk of compatibility issues and simplifying maintenance and replacement procedures.

b. Reliability and Performance: By adhering to product standards, relay socket manufacturers ensure that their products meet specific performance criteria, resulting in reliable and consistent operation. This reliability is crucial in critical applications where system failure can have severe consequences.

c. Safety Assurance: Compliance with safety standards guarantees that relay sockets are designed and manufactured to meet stringent safety requirements, minimizing the risk of electrical hazards and ensuring user safety.

d. Global Acceptance: International product standards provide a common language for manufacturers, suppliers, and customers worldwide. Complying with these standards ensures global acceptance and facilitates trade across different regions.

e. Regulatory Compliance: Many industries have specific regulations and standards that must be met. By using relay sockets that comply with relevant product standards, manufacturers can ensure compliance with industry-specific regulations, avoiding legal and regulatory issues.

Conclusion (100 words) Relay sockets are critical components in electrical systems, and adherence to product standards is essential to ensure their reliability, compatibility, and safety. By understanding the importance of product standards, key specifications, and the benefits they offer, engineers and technicians can make informed decisions when selecting relay sockets for their applications. Compliance with these standards not only ensures optimal performance but also contributes to the overall efficiency and longevity of electrical systems.