Title: Key Lock Switch Production Processes: A Comprehensive Overview

1. Design and Engineering (200 words) The production of key lock switches begins with the design and engineering phase. This stage involves conceptualizing the switch's functionality, aesthetics, and compatibility with different applications. Designers consider factors such as key shape, lock mechanism, and electrical specifications. Computer-aided design (CAD) software is often employed to create detailed 2D and 3D models, allowing for precise visualization and modification.

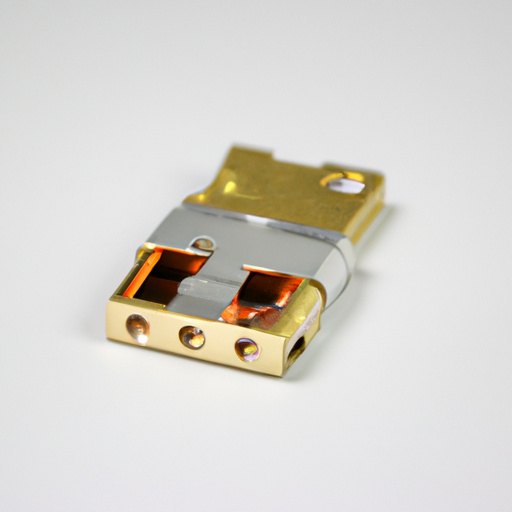

2. Material Selection (150 words) Choosing the appropriate materials is crucial for key lock switch production. The switch's housing, key, lock cylinder, and internal components must be durable, corrosion-resistant, and capable of withstanding repetitive use. Common materials include stainless steel, brass, zinc alloy, and high-quality plastics. Material selection is based on factors such as cost, application requirements, and environmental considerations.

3. Injection Molding (250 words) Injection molding is a widely used manufacturing process for producing key lock switch components. It involves injecting molten material into a mold cavity, allowing it to cool and solidify. This process is highly efficient, enabling the production of complex shapes with high precision and repeatability. Injection molding is commonly used for manufacturing switch housings, keys, and other plastic components.

4. Metal Stamping (200 words) Metal stamping is employed for producing key lock switch components made from metal, such as lock cylinders and internal mechanisms. This process involves feeding a metal sheet into a stamping press, which applies pressure to shape the metal into the desired form. Metal stamping offers high production rates, excellent dimensional accuracy, and cost-effectiveness for large-scale manufacturing.

5. Assembly and Testing (250 words) Once the individual components are manufactured, they are assembled to create the final key lock switch. This process involves fitting the lock cylinder, internal mechanisms, and other components into the housing. Adhesives, screws, or other fastening methods may be used to secure the components together. After assembly, each switch undergoes rigorous testing to ensure proper functionality, including key insertion, rotation, and electrical contact.

6. Surface Finishing (150 words) Surface finishing is an essential step in key lock switch production, enhancing the switch's appearance, durability, and resistance to corrosion. Common surface finishing techniques include electroplating, powder coating, and painting. Electroplating, such as nickel or chrome plating, provides a protective layer and improves the switch's aesthetic appeal. Powder coating and painting offer a wide range of color options while providing a durable and scratch-resistant finish.

Conclusion (100 words) The production of key lock switches involves a series of well-defined processes, from design and engineering to assembly and surface finishing. Each step plays a crucial role in ensuring the switch's functionality, durability, and aesthetic appeal. By understanding these production processes, manufacturers can optimize their operations, resulting in high-quality key lock switches that meet the diverse needs of various industries.

Title: Key Lock Switch Production Processes: A Comprehensive Overview

1. Design and Engineering (200 words) The production of key lock switches begins with the design and engineering phase. This stage involves conceptualizing the switch's functionality, aesthetics, and compatibility with different applications. Designers consider factors such as key shape, lock mechanism, and electrical specifications. Computer-aided design (CAD) software is often employed to create detailed 2D and 3D models, allowing for precise visualization and modification.

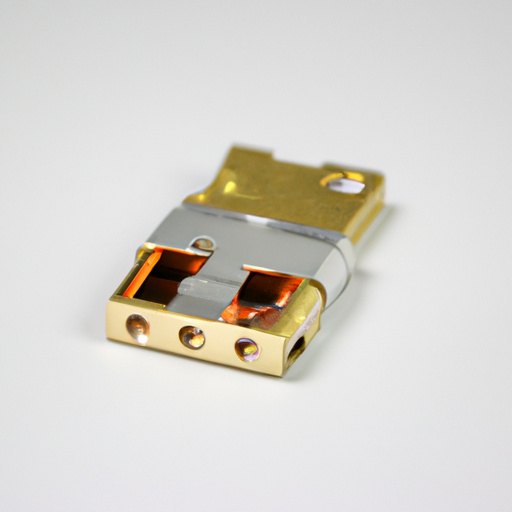

2. Material Selection (150 words) Choosing the appropriate materials is crucial for key lock switch production. The switch's housing, key, lock cylinder, and internal components must be durable, corrosion-resistant, and capable of withstanding repetitive use. Common materials include stainless steel, brass, zinc alloy, and high-quality plastics. Material selection is based on factors such as cost, application requirements, and environmental considerations.

3. Injection Molding (250 words) Injection molding is a widely used manufacturing process for producing key lock switch components. It involves injecting molten material into a mold cavity, allowing it to cool and solidify. This process is highly efficient, enabling the production of complex shapes with high precision and repeatability. Injection molding is commonly used for manufacturing switch housings, keys, and other plastic components.

4. Metal Stamping (200 words) Metal stamping is employed for producing key lock switch components made from metal, such as lock cylinders and internal mechanisms. This process involves feeding a metal sheet into a stamping press, which applies pressure to shape the metal into the desired form. Metal stamping offers high production rates, excellent dimensional accuracy, and cost-effectiveness for large-scale manufacturing.

5. Assembly and Testing (250 words) Once the individual components are manufactured, they are assembled to create the final key lock switch. This process involves fitting the lock cylinder, internal mechanisms, and other components into the housing. Adhesives, screws, or other fastening methods may be used to secure the components together. After assembly, each switch undergoes rigorous testing to ensure proper functionality, including key insertion, rotation, and electrical contact.

6. Surface Finishing (150 words) Surface finishing is an essential step in key lock switch production, enhancing the switch's appearance, durability, and resistance to corrosion. Common surface finishing techniques include electroplating, powder coating, and painting. Electroplating, such as nickel or chrome plating, provides a protective layer and improves the switch's aesthetic appeal. Powder coating and painting offer a wide range of color options while providing a durable and scratch-resistant finish.

Conclusion (100 words) The production of key lock switches involves a series of well-defined processes, from design and engineering to assembly and surface finishing. Each step plays a crucial role in ensuring the switch's functionality, durability, and aesthetic appeal. By understanding these production processes, manufacturers can optimize their operations, resulting in high-quality key lock switches that meet the diverse needs of various industries.