Title: Rotary Switch Components: A Comprehensive Guide for Electronic Applications

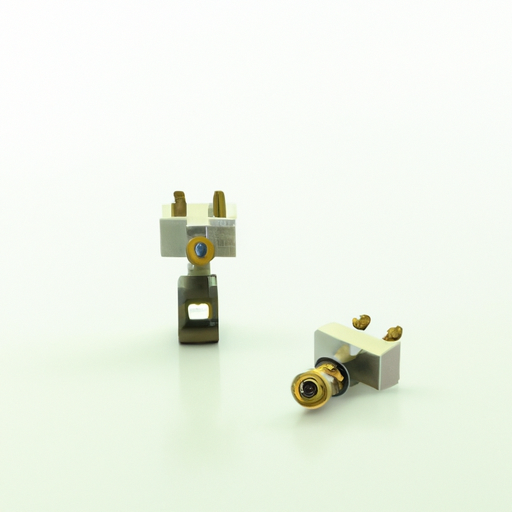

I. Understanding Rotary Switch Components: 1. Definition and Basic Structure: - Rotary switches are electromechanical devices that allow users to select different circuit paths by rotating a knob or lever. - They consist of a rotating spindle, stationary contacts, and a wiper arm that bridges the contacts as the switch is turned.

2. Types of Rotary Switches: - Single Pole, Single Throw (SPST) Switches: These switches have a single circuit path and are commonly used for on/off functions. - Single Pole, Double Throw (SPDT) Switches: These switches have two circuit paths and are used for selecting between two options. - Multi-Pole, Multi-Throw (MPMT) Switches: These switches have multiple circuit paths and are suitable for complex applications.

II. Working Principles of Rotary Switches: 1. Contact Arrangements: - Rotary switches can have various contact arrangements, including single-level, multi-level, and make-before-break configurations. - Single-level switches connect one contact at a time, while multi-level switches can connect multiple contacts simultaneously. - Make-before-break switches ensure a continuous connection during switching, preventing momentary interruptions.

2. Switching Mechanisms: - Rotary switches can employ different mechanisms, such as detent, spring-loaded, or indexing mechanisms, to provide tactile feedback and precise positioning. - Detent mechanisms offer distinct positions with a click-like feel, while spring-loaded mechanisms return the switch to a default position when released. - Indexing mechanisms provide a smooth rotation with predefined positions, commonly used in applications requiring precise alignment.

III. Key Considerations for Selecting Rotary Switch Components: 1. Electrical Ratings: - Consider the voltage and current requirements of the application to ensure the switch can handle the load without causing overheating or failure. - Pay attention to the maximum voltage and current ratings specified by the manufacturer.

2. Environmental Factors: - Determine the operating temperature range, humidity, and exposure to dust, moisture, or chemicals to select a switch with suitable environmental protection. - Consider switches with sealed or IP-rated enclosures for harsh environments.

3. Mechanical Durability: - Evaluate the expected number of switch cycles and select a switch with a sufficient mechanical lifespan. - Look for switches with gold-plated contacts for improved durability and reduced contact resistance.

4. Mounting Options: - Consider the available space and mounting requirements of the application. - Rotary switches are available in various mounting styles, including panel mount, PCB mount, and solder lug options.

5. Size and Configuration: - Choose a switch size and configuration that aligns with the application's design constraints. - Consider the number of poles and throws required for the desired circuit selection.

Conclusion: Rotary switches are versatile components that play a crucial role in electronic devices, offering reliable circuit selection and control. Understanding the different types, working principles, and key considerations for selecting rotary switch components is essential for ensuring optimal performance and longevity in various applications. By considering electrical ratings, environmental factors, mechanical durability, mounting options, and size/configuration requirements, engineers and designers can make informed decisions when choosing rotary switches for their projects.

Title: Rotary Switch Components: A Comprehensive Guide for Electronic Applications

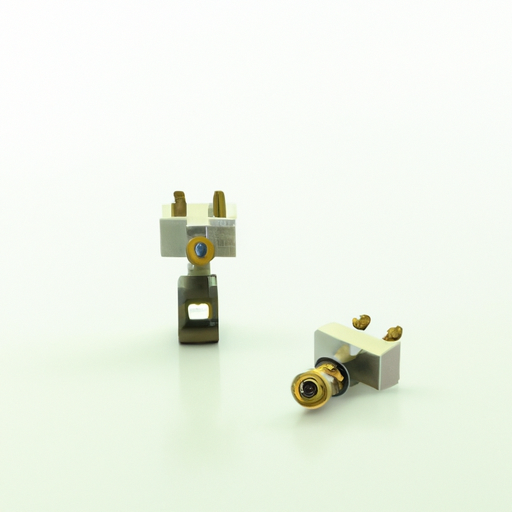

I. Understanding Rotary Switch Components: 1. Definition and Basic Structure: - Rotary switches are electromechanical devices that allow users to select different circuit paths by rotating a knob or lever. - They consist of a rotating spindle, stationary contacts, and a wiper arm that bridges the contacts as the switch is turned.

2. Types of Rotary Switches: - Single Pole, Single Throw (SPST) Switches: These switches have a single circuit path and are commonly used for on/off functions. - Single Pole, Double Throw (SPDT) Switches: These switches have two circuit paths and are used for selecting between two options. - Multi-Pole, Multi-Throw (MPMT) Switches: These switches have multiple circuit paths and are suitable for complex applications.

II. Working Principles of Rotary Switches: 1. Contact Arrangements: - Rotary switches can have various contact arrangements, including single-level, multi-level, and make-before-break configurations. - Single-level switches connect one contact at a time, while multi-level switches can connect multiple contacts simultaneously. - Make-before-break switches ensure a continuous connection during switching, preventing momentary interruptions.

2. Switching Mechanisms: - Rotary switches can employ different mechanisms, such as detent, spring-loaded, or indexing mechanisms, to provide tactile feedback and precise positioning. - Detent mechanisms offer distinct positions with a click-like feel, while spring-loaded mechanisms return the switch to a default position when released. - Indexing mechanisms provide a smooth rotation with predefined positions, commonly used in applications requiring precise alignment.

III. Key Considerations for Selecting Rotary Switch Components: 1. Electrical Ratings: - Consider the voltage and current requirements of the application to ensure the switch can handle the load without causing overheating or failure. - Pay attention to the maximum voltage and current ratings specified by the manufacturer.

2. Environmental Factors: - Determine the operating temperature range, humidity, and exposure to dust, moisture, or chemicals to select a switch with suitable environmental protection. - Consider switches with sealed or IP-rated enclosures for harsh environments.

3. Mechanical Durability: - Evaluate the expected number of switch cycles and select a switch with a sufficient mechanical lifespan. - Look for switches with gold-plated contacts for improved durability and reduced contact resistance.

4. Mounting Options: - Consider the available space and mounting requirements of the application. - Rotary switches are available in various mounting styles, including panel mount, PCB mount, and solder lug options.

5. Size and Configuration: - Choose a switch size and configuration that aligns with the application's design constraints. - Consider the number of poles and throws required for the desired circuit selection.

Conclusion: Rotary switches are versatile components that play a crucial role in electronic devices, offering reliable circuit selection and control. Understanding the different types, working principles, and key considerations for selecting rotary switch components is essential for ensuring optimal performance and longevity in various applications. By considering electrical ratings, environmental factors, mechanical durability, mounting options, and size/configuration requirements, engineers and designers can make informed decisions when choosing rotary switches for their projects.