The card edge connector industry is constantly evolving to meet the demands of modern technology. As electronic devices become smaller, faster, and more complex, the need for reliable and efficient connectors has never been greater. In this article, we will explore some of the key trends shaping the card edge connector industry today.

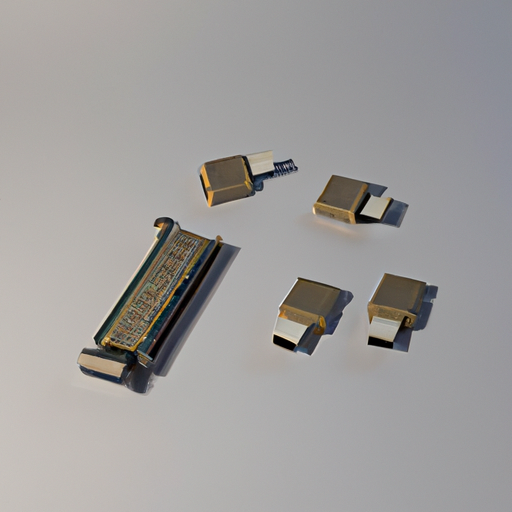

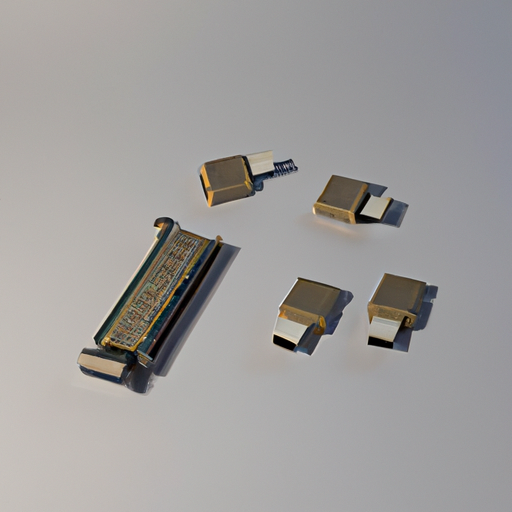

One of the most significant trends in the card edge connector industry is the ongoing trend towards miniaturization. As electronic devices become smaller and more compact, the connectors that link various components together must also shrink in size. This trend has led to the development of smaller and more compact card edge connectors that can accommodate the tight spacing requirements of modern electronics.

Miniaturization has also driven advancements in connector design, with manufacturers developing new materials and manufacturing techniques to create connectors that are smaller, lighter, and more durable than ever before. These advancements have enabled the development of ultra-thin connectors that can be used in a wide range of applications, from smartphones and tablets to wearable devices and IoT sensors.

2. High-speed data transmission

Another key trend in the card edge connector industry is the increasing demand for high-speed data transmission. As electronic devices become more powerful and data-intensive, the need for connectors that can support high-speed data transfer rates has become paramount. This trend has led to the development of card edge connectors that are capable of supporting data rates of up to 10 Gbps or higher.

To achieve these high data rates, manufacturers have incorporated advanced signal integrity features into their connectors, such as controlled impedance, differential signaling, and low crosstalk. These features help to minimize signal degradation and ensure reliable data transmission even at high speeds.

3. Increased reliability and durability

Reliability and durability are also key trends in the card edge connector industry. As electronic devices become more integral to our daily lives, the need for connectors that can withstand the rigors of everyday use has become increasingly important. Manufacturers are therefore focusing on developing connectors that are not only reliable but also durable enough to withstand repeated insertions and removals.

To achieve this, manufacturers are using high-quality materials such as gold-plated contacts and ruggedized housings to ensure that their connectors can withstand the demands of modern electronics. In addition, manufacturers are also investing in advanced testing and quality control processes to ensure that their connectors meet the highest standards of reliability and durability.

4. Customization and flexibility

As electronic devices become more diverse and specialized, the demand for customized connectors has also increased. Manufacturers are therefore offering a wider range of customization options to meet the unique requirements of different applications. This trend has led to the development of connectors that can be customized in terms of pin configuration, contact spacing, and mounting options to suit a wide range of applications.

Customization options also extend to the materials used in connectors, with manufacturers offering a variety of plating options, housing materials, and contact materials to meet the specific needs of different applications. This trend towards customization and flexibility has enabled manufacturers to cater to a wider range of industries and applications, from automotive and aerospace to medical and industrial.

5. Sustainability and environmental responsibility

Sustainability and environmental responsibility are becoming increasingly important considerations in the card edge connector industry. As electronic waste continues to be a growing concern, manufacturers are focusing on developing connectors that are more environmentally friendly and sustainable. This trend has led to the development of connectors that are RoHS-compliant, lead-free, and recyclable.

Manufacturers are also investing in sustainable manufacturing practices, such as using renewable energy sources and reducing waste and emissions. By prioritizing sustainability and environmental responsibility, manufacturers are not only meeting regulatory requirements but also demonstrating their commitment to reducing their environmental impact.

In conclusion, the card edge connector industry is experiencing a number of key trends that are shaping the future of connector technology. From miniaturization and high-speed data transmission to increased reliability and customization, manufacturers are constantly innovating to meet the evolving demands of modern electronics. By staying ahead of these trends and embracing new technologies, manufacturers can continue to drive the industry forward and meet the needs of a wide range of industries and applications.

The card edge connector industry is constantly evolving to meet the demands of modern technology. As electronic devices become smaller, faster, and more complex, the need for reliable and efficient connectors has never been greater. In this article, we will explore some of the key trends shaping the card edge connector industry today.

One of the most significant trends in the card edge connector industry is the ongoing trend towards miniaturization. As electronic devices become smaller and more compact, the connectors that link various components together must also shrink in size. This trend has led to the development of smaller and more compact card edge connectors that can accommodate the tight spacing requirements of modern electronics.

Miniaturization has also driven advancements in connector design, with manufacturers developing new materials and manufacturing techniques to create connectors that are smaller, lighter, and more durable than ever before. These advancements have enabled the development of ultra-thin connectors that can be used in a wide range of applications, from smartphones and tablets to wearable devices and IoT sensors.

2. High-speed data transmission

Another key trend in the card edge connector industry is the increasing demand for high-speed data transmission. As electronic devices become more powerful and data-intensive, the need for connectors that can support high-speed data transfer rates has become paramount. This trend has led to the development of card edge connectors that are capable of supporting data rates of up to 10 Gbps or higher.

To achieve these high data rates, manufacturers have incorporated advanced signal integrity features into their connectors, such as controlled impedance, differential signaling, and low crosstalk. These features help to minimize signal degradation and ensure reliable data transmission even at high speeds.

3. Increased reliability and durability

Reliability and durability are also key trends in the card edge connector industry. As electronic devices become more integral to our daily lives, the need for connectors that can withstand the rigors of everyday use has become increasingly important. Manufacturers are therefore focusing on developing connectors that are not only reliable but also durable enough to withstand repeated insertions and removals.

To achieve this, manufacturers are using high-quality materials such as gold-plated contacts and ruggedized housings to ensure that their connectors can withstand the demands of modern electronics. In addition, manufacturers are also investing in advanced testing and quality control processes to ensure that their connectors meet the highest standards of reliability and durability.

4. Customization and flexibility

As electronic devices become more diverse and specialized, the demand for customized connectors has also increased. Manufacturers are therefore offering a wider range of customization options to meet the unique requirements of different applications. This trend has led to the development of connectors that can be customized in terms of pin configuration, contact spacing, and mounting options to suit a wide range of applications.

Customization options also extend to the materials used in connectors, with manufacturers offering a variety of plating options, housing materials, and contact materials to meet the specific needs of different applications. This trend towards customization and flexibility has enabled manufacturers to cater to a wider range of industries and applications, from automotive and aerospace to medical and industrial.

5. Sustainability and environmental responsibility

Sustainability and environmental responsibility are becoming increasingly important considerations in the card edge connector industry. As electronic waste continues to be a growing concern, manufacturers are focusing on developing connectors that are more environmentally friendly and sustainable. This trend has led to the development of connectors that are RoHS-compliant, lead-free, and recyclable.

Manufacturers are also investing in sustainable manufacturing practices, such as using renewable energy sources and reducing waste and emissions. By prioritizing sustainability and environmental responsibility, manufacturers are not only meeting regulatory requirements but also demonstrating their commitment to reducing their environmental impact.

In conclusion, the card edge connector industry is experiencing a number of key trends that are shaping the future of connector technology. From miniaturization and high-speed data transmission to increased reliability and customization, manufacturers are constantly innovating to meet the evolving demands of modern electronics. By staying ahead of these trends and embracing new technologies, manufacturers can continue to drive the industry forward and meet the needs of a wide range of industries and applications.