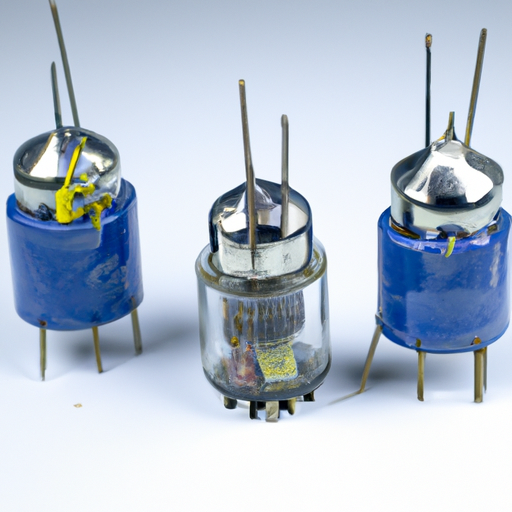

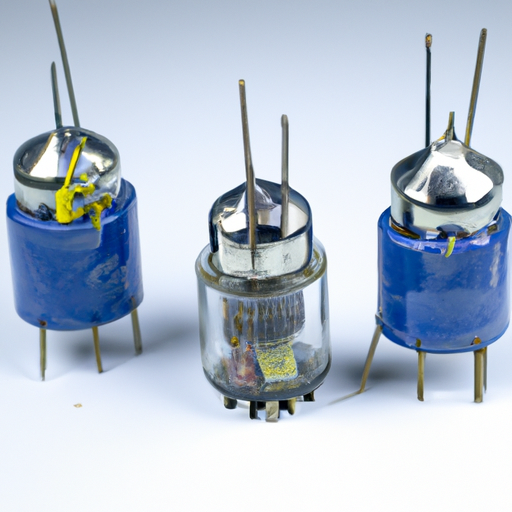

Title: Understanding Product Standards for Rectifiers: A Comprehensive Guide

1. Definition and Importance of Product Standards (200 words) Product standards are a set of guidelines and specifications that define the quality, safety, and performance requirements for a particular product. They are developed by standardization organizations, regulatory bodies, and industry associations to ensure consistency, reliability, and interoperability across various products. For rectifiers, product standards are crucial as they guarantee the rectifier's compliance with safety regulations, electrical performance, and environmental considerations.

2. Safety Standards for Rectifiers (300 words) Safety is of paramount importance when it comes to rectifiers, as they deal with high voltages and currents. Several safety standards govern rectifiers, including:

a) International Electrotechnical Commission (IEC) 60950: This standard ensures the safety of information technology equipment, including rectifiers, by addressing electrical, mechanical, and fire hazards.

b) Underwriters Laboratories (UL) 60950: Similar to IEC 60950, UL 60950 focuses on safety requirements for information technology equipment, including rectifiers, in the United States.

c) Restriction of Hazardous Substances (RoHS): RoHS compliance ensures that rectifiers do not contain hazardous substances such as lead, mercury, cadmium, and certain flame retardants, minimizing environmental and health risks.

3. Electrical Performance Standards for Rectifiers (400 words) To ensure reliable and efficient operation, rectifiers must meet specific electrical performance standards. These standards include:

a) Voltage Regulation: Voltage regulation standards define the acceptable range of output voltage variation under different load conditions. For example, the Institute of Electrical and Electronics Engineers (IEEE) 519 standard specifies voltage distortion limits to prevent harmonic distortion in power systems.

b) Efficiency: Efficiency standards determine the energy conversion efficiency of rectifiers, ensuring minimal power losses during the conversion process. Standards such as the European Union's Eco-Design Directive set minimum efficiency requirements for rectifiers to promote energy conservation.

c) Power Factor Correction (PFC): PFC standards aim to improve the power factor of rectifiers, reducing reactive power consumption and improving overall energy efficiency. The IEC 61000-3-2 standard sets limits on harmonic currents generated by rectifiers to maintain power quality in electrical networks.

4. Environmental Standards for Rectifiers (300 words) In today's environmentally conscious world, rectifiers must comply with various environmental standards. These standards include:

a) Energy Star: The Energy Star program, initiated by the U.S. Environmental Protection Agency (EPA), certifies energy-efficient products, including rectifiers. Energy Star-certified rectifiers consume less energy during operation, reducing greenhouse gas emissions and energy costs.

b) Waste Electrical and Electronic Equipment (WEEE) Directive: The WEEE Directive aims to minimize the environmental impact of electronic waste. Rectifiers must comply with this directive, ensuring proper disposal, recycling, and recovery of materials at the end of their life cycle.

c) ISO 14001: This international standard focuses on environmental management systems. Manufacturers can obtain ISO 14001 certification by implementing effective environmental management practices, including waste reduction, energy conservation, and pollution prevention.

Conclusion (100 words) Product standards for rectifiers are essential to ensure their safety, electrical performance, and environmental sustainability. Compliance with these standards not only guarantees the quality and reliability of rectifiers but also promotes energy efficiency and reduces environmental impact. Manufacturers, engineers, and consumers should be aware of these standards to make informed decisions when selecting and utilizing rectifiers. By adhering to product standards, the industry can continue to innovate and provide safe, efficient, and environmentally friendly rectifiers for various applications.

Title: Understanding Product Standards for Rectifiers: A Comprehensive Guide

1. Definition and Importance of Product Standards (200 words) Product standards are a set of guidelines and specifications that define the quality, safety, and performance requirements for a particular product. They are developed by standardization organizations, regulatory bodies, and industry associations to ensure consistency, reliability, and interoperability across various products. For rectifiers, product standards are crucial as they guarantee the rectifier's compliance with safety regulations, electrical performance, and environmental considerations.

2. Safety Standards for Rectifiers (300 words) Safety is of paramount importance when it comes to rectifiers, as they deal with high voltages and currents. Several safety standards govern rectifiers, including:

a) International Electrotechnical Commission (IEC) 60950: This standard ensures the safety of information technology equipment, including rectifiers, by addressing electrical, mechanical, and fire hazards.

b) Underwriters Laboratories (UL) 60950: Similar to IEC 60950, UL 60950 focuses on safety requirements for information technology equipment, including rectifiers, in the United States.

c) Restriction of Hazardous Substances (RoHS): RoHS compliance ensures that rectifiers do not contain hazardous substances such as lead, mercury, cadmium, and certain flame retardants, minimizing environmental and health risks.

3. Electrical Performance Standards for Rectifiers (400 words) To ensure reliable and efficient operation, rectifiers must meet specific electrical performance standards. These standards include:

a) Voltage Regulation: Voltage regulation standards define the acceptable range of output voltage variation under different load conditions. For example, the Institute of Electrical and Electronics Engineers (IEEE) 519 standard specifies voltage distortion limits to prevent harmonic distortion in power systems.

b) Efficiency: Efficiency standards determine the energy conversion efficiency of rectifiers, ensuring minimal power losses during the conversion process. Standards such as the European Union's Eco-Design Directive set minimum efficiency requirements for rectifiers to promote energy conservation.

c) Power Factor Correction (PFC): PFC standards aim to improve the power factor of rectifiers, reducing reactive power consumption and improving overall energy efficiency. The IEC 61000-3-2 standard sets limits on harmonic currents generated by rectifiers to maintain power quality in electrical networks.

4. Environmental Standards for Rectifiers (300 words) In today's environmentally conscious world, rectifiers must comply with various environmental standards. These standards include:

a) Energy Star: The Energy Star program, initiated by the U.S. Environmental Protection Agency (EPA), certifies energy-efficient products, including rectifiers. Energy Star-certified rectifiers consume less energy during operation, reducing greenhouse gas emissions and energy costs.

b) Waste Electrical and Electronic Equipment (WEEE) Directive: The WEEE Directive aims to minimize the environmental impact of electronic waste. Rectifiers must comply with this directive, ensuring proper disposal, recycling, and recovery of materials at the end of their life cycle.

c) ISO 14001: This international standard focuses on environmental management systems. Manufacturers can obtain ISO 14001 certification by implementing effective environmental management practices, including waste reduction, energy conservation, and pollution prevention.

Conclusion (100 words) Product standards for rectifiers are essential to ensure their safety, electrical performance, and environmental sustainability. Compliance with these standards not only guarantees the quality and reliability of rectifiers but also promotes energy efficiency and reduces environmental impact. Manufacturers, engineers, and consumers should be aware of these standards to make informed decisions when selecting and utilizing rectifiers. By adhering to product standards, the industry can continue to innovate and provide safe, efficient, and environmentally friendly rectifiers for various applications.