Title: Product Standards for Transformers: Ensuring Efficiency and Safety

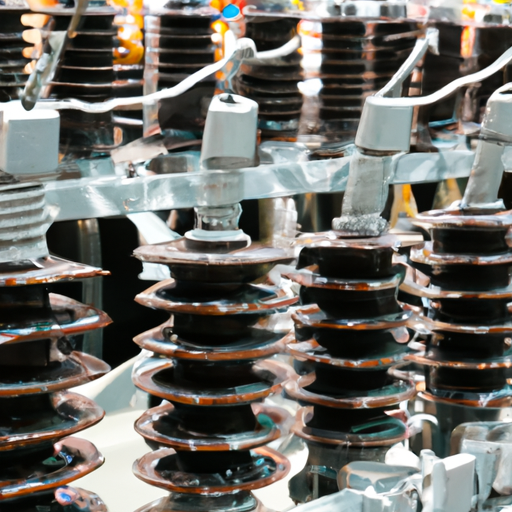

1. Design Standards (200 words) Design standards for transformers focus on the overall construction and configuration of the equipment. These standards ensure that transformers are designed to meet specific requirements, such as voltage levels, power ratings, and environmental conditions. Key design standards include:

a) IEC 60076: This international standard provides guidelines for the design, manufacturing, and testing of power transformers. It covers aspects such as insulation, cooling systems, and mechanical strength.

b) ANSI/IEEE C57: These standards, developed by the American National Standards Institute (ANSI) and the Institute of Electrical and Electronics Engineers (IEEE), outline design requirements for power transformers, including insulation levels, temperature rise limits, and load capacity.

2. Construction Standards (300 words) Construction standards focus on the materials, components, and manufacturing processes used in transformer production. These standards ensure that transformers are built to withstand electrical, thermal, and mechanical stresses. Key construction standards include:

a) IEC 60076-1: This standard specifies general requirements for power transformers, including materials, insulation systems, and mechanical structures. It also covers safety aspects, such as protection against fire and explosion hazards.

b) NEMA TR-1: Developed by the National Electrical Manufacturers Association (NEMA), this standard provides guidelines for the construction and testing of dry-type transformers. It covers aspects such as winding insulation, core construction, and cooling systems.

3. Testing Standards (300 words) Testing standards are crucial to verify the performance, efficiency, and safety of transformers. These standards ensure that transformers meet specified requirements and can operate reliably under various conditions. Key testing standards include:

a) IEC 60076-3: This standard outlines the procedures for conducting routine and special tests on power transformers. It covers aspects such as insulation resistance, load loss, and short-circuit withstand capability.

b) ANSI/IEEE C57.12: These standards specify the methods and procedures for testing liquid-immersed power transformers. They cover aspects such as dielectric tests, temperature rise tests, and impulse tests.

4. Performance Standards (300 words) Performance standards focus on the operational characteristics and efficiency of transformers. These standards ensure that transformers deliver the expected performance while minimizing losses and environmental impact. Key performance standards include:

a) IEC 60076-11: This standard provides guidelines for the determination of transformer losses and efficiency. It specifies the test methods and calculation procedures to assess the energy performance of transformers.

b) ENERGY STAR: This voluntary program, administered by the U.S. Environmental Protection Agency (EPA), sets energy efficiency standards for various appliances, including transformers. Transformers meeting ENERGY STAR requirements are recognized for their energy-saving capabilities.

Conclusion (100 words) Product standards for transformers are essential to ensure their efficiency, reliability, and safety in electrical power systems. These standards encompass design, construction, testing, and performance criteria, providing guidelines for manufacturers, installers, and users. Adhering to these standards not only guarantees the optimal performance of transformers but also contributes to energy conservation and environmental sustainability. By complying with these standards, the industry can continue to advance and innovate, meeting the evolving needs of modern power systems while ensuring the highest levels of efficiency and safety.

Title: Product Standards for Transformers: Ensuring Efficiency and Safety

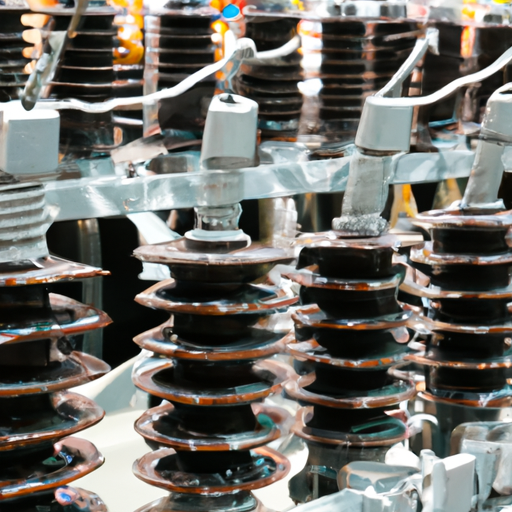

1. Design Standards (200 words) Design standards for transformers focus on the overall construction and configuration of the equipment. These standards ensure that transformers are designed to meet specific requirements, such as voltage levels, power ratings, and environmental conditions. Key design standards include:

a) IEC 60076: This international standard provides guidelines for the design, manufacturing, and testing of power transformers. It covers aspects such as insulation, cooling systems, and mechanical strength.

b) ANSI/IEEE C57: These standards, developed by the American National Standards Institute (ANSI) and the Institute of Electrical and Electronics Engineers (IEEE), outline design requirements for power transformers, including insulation levels, temperature rise limits, and load capacity.

2. Construction Standards (300 words) Construction standards focus on the materials, components, and manufacturing processes used in transformer production. These standards ensure that transformers are built to withstand electrical, thermal, and mechanical stresses. Key construction standards include:

a) IEC 60076-1: This standard specifies general requirements for power transformers, including materials, insulation systems, and mechanical structures. It also covers safety aspects, such as protection against fire and explosion hazards.

b) NEMA TR-1: Developed by the National Electrical Manufacturers Association (NEMA), this standard provides guidelines for the construction and testing of dry-type transformers. It covers aspects such as winding insulation, core construction, and cooling systems.

3. Testing Standards (300 words) Testing standards are crucial to verify the performance, efficiency, and safety of transformers. These standards ensure that transformers meet specified requirements and can operate reliably under various conditions. Key testing standards include:

a) IEC 60076-3: This standard outlines the procedures for conducting routine and special tests on power transformers. It covers aspects such as insulation resistance, load loss, and short-circuit withstand capability.

b) ANSI/IEEE C57.12: These standards specify the methods and procedures for testing liquid-immersed power transformers. They cover aspects such as dielectric tests, temperature rise tests, and impulse tests.

4. Performance Standards (300 words) Performance standards focus on the operational characteristics and efficiency of transformers. These standards ensure that transformers deliver the expected performance while minimizing losses and environmental impact. Key performance standards include:

a) IEC 60076-11: This standard provides guidelines for the determination of transformer losses and efficiency. It specifies the test methods and calculation procedures to assess the energy performance of transformers.

b) ENERGY STAR: This voluntary program, administered by the U.S. Environmental Protection Agency (EPA), sets energy efficiency standards for various appliances, including transformers. Transformers meeting ENERGY STAR requirements are recognized for their energy-saving capabilities.

Conclusion (100 words) Product standards for transformers are essential to ensure their efficiency, reliability, and safety in electrical power systems. These standards encompass design, construction, testing, and performance criteria, providing guidelines for manufacturers, installers, and users. Adhering to these standards not only guarantees the optimal performance of transformers but also contributes to energy conservation and environmental sustainability. By complying with these standards, the industry can continue to advance and innovate, meeting the evolving needs of modern power systems while ensuring the highest levels of efficiency and safety.